Abstract

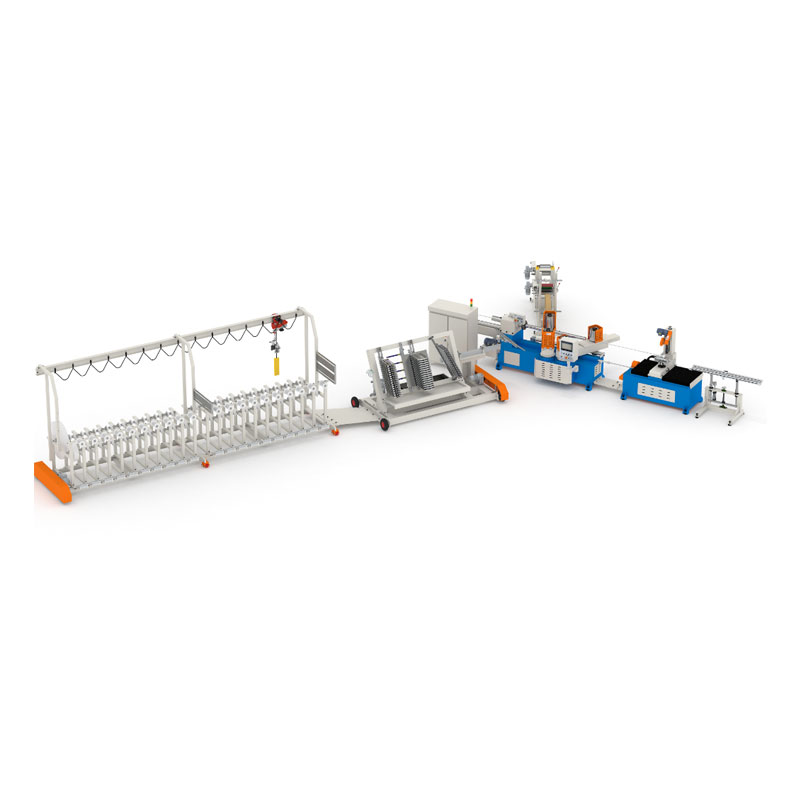

A Coating Machine is often treated like a “single piece of equipment,” but your real output quality is the result of a full system: coating head + web handling + drying/curing + tension control + process repeatability. When any one of those drifts, you get the classic pain points—scrap, customer complaints, and a line that only runs “well” under one perfect operator.

This guide breaks down the most common production headaches (and why they happen), then turns them into a clear selection and implementation checklist. You’ll also get a simple table to match defects to solutions, plus a FAQ to help you align your technical team and procurement team before you request quotations.

Table of Contents

Outline

- Identify the production pain points that cost you the most per week (scrap, downtime, rework, claims).

- Map those pain points to the coating system components that control them (web handling, coating head, drying/curing, controls).

- Use a defect-to-fix reference table to avoid “feature shopping” and focus on measurable outcomes.

- Apply a selection checklist to compare different Coating Machine configurations fairly.

- Plan commissioning and operator habits so the line performs consistently across shifts.

The pain points buyers mention first

1) “Our coating weight isn’t stable.”

This usually shows up as thickness variation across the width, inconsistent gloss, or functional failures (barrier, adhesion, conductivity, etc.). The root causes often include tension drift, poor metering stability, or a drying profile that “moves” the coating after application.

2) “Defects spike after stops and splices.”

Start/stop events create pressure changes, air entrainment, and temperature swings. If your machine lacks repeatable recipes, stable tension zones, and an operator-friendly restart routine, the first 50–200 meters can turn into planned scrap.

3) “Changeovers take too long (and make a mess).”

Cleaning and viscosity stabilization can eat your throughput. A smart configuration reduces dead zones, uses quick-release components, and supports predictable flushing/cleaning without disassembling half the line.

4) “Drying is our bottleneck.”

Many lines apply coating faster than they can dry it safely and uniformly. The result is blocking, solvent retention, curl, odor complaints, or downstream lamination failures.

Here’s the uncomfortable truth: most “coating problems” are not fixed by chasing only a better coating head. You fix them by making the whole Coating Machine behave like a repeatable process—not a personality test for operators.

Why coating performance is a system

Think of a Coating Machine as four linked control zones. If you evaluate them separately, you’ll likely buy the wrong upgrades.

- Web handling and tension control: Stable unwind/rewind torque, aligned rollers, and properly designed tension zones prevent wrinkles, wandering edges, and thickness variation across width.

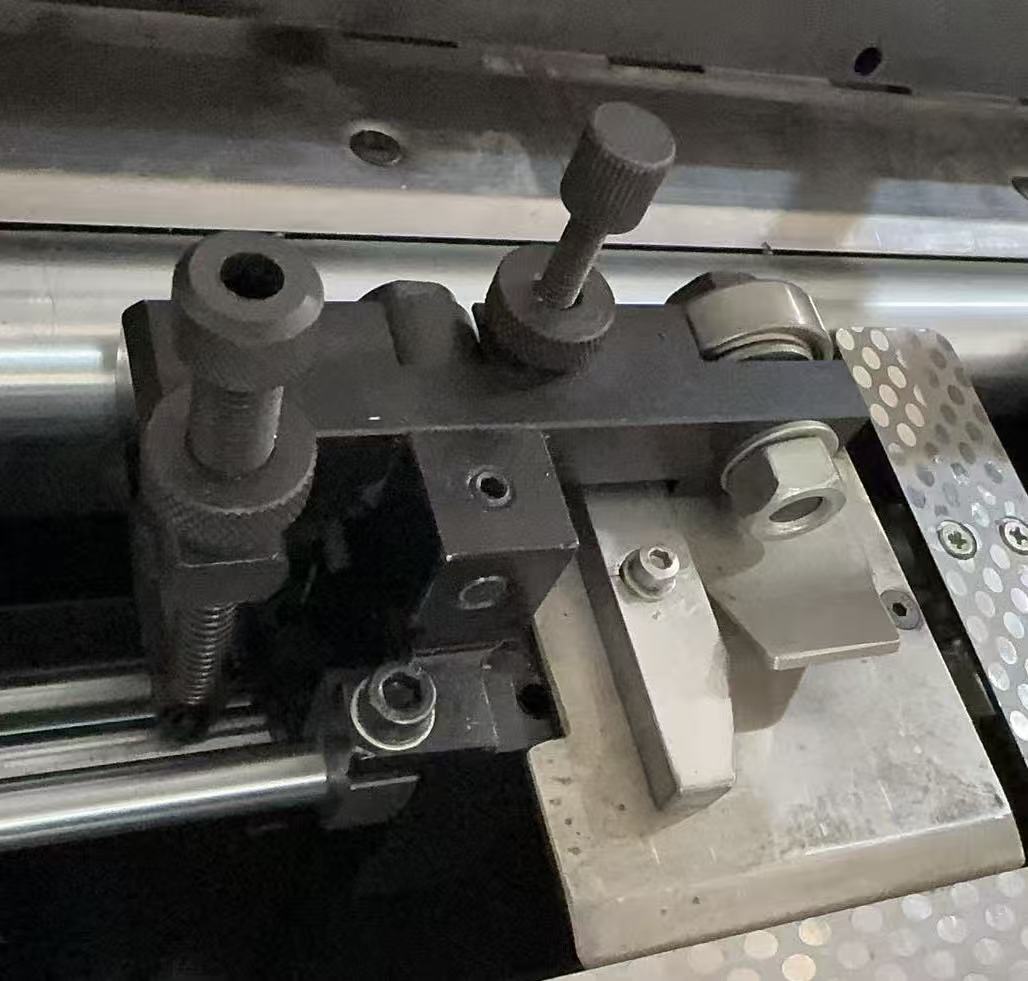

- Coating application and metering: The coating method (e.g., gravure, reverse roll, knife-over-roll, slot-die, comma) should match your material behavior—viscosity, solids content, and required coating weight range.

- Drying/curing and airflow: A drying system that ramps temperature and airflow in a controlled way avoids skinning, bubbles, or “drag marks.” It also protects functional coatings that are sensitive to heat.

- Controls and repeatability: Recipe storage, stable speed control, and clear operator interfaces reduce variability between shifts and shorten the time to stable production after changeover.

Buyer tip: When suppliers propose a solution, ask them to explain which of these four zones they’re improving and what metric should move (scrap %, coating weight tolerance, changeover minutes, line speed at target dryness).

Defects-to-fixes table

Use this table as a quick diagnostic. It doesn’t replace lab work, but it keeps discussions grounded when multiple stakeholders are involved.

| Common issue on the roll | What it often means | Machine-side fixes that help |

|---|---|---|

| Streaks / lines in coating | Contamination, unstable metering, roller runout, or uneven pressure | Cleaner fluid path, precision rollers, stable nip/metering adjustment, improved filtration, better tension stability |

| Pinhole / fish-eye | Surface energy mismatch, air entrainment, dust, or foaming | Web cleaning/ionization, controlled coating head geometry, deaeration/filtration options, calmer flow zones |

| Wrinkles / edge waves | Tension imbalance, poor alignment, uneven drying shrink | Multi-zone tension control, guiding/correction, improved dryer profile and airflow distribution |

| Tacky finish / blocking | Insufficient drying/curing or solvent retention | Upgraded drying length or airflow, staged temperature control, better exhaust balance, inline monitoring where applicable |

| Coating weight variation | Speed fluctuation, viscosity drift, unstable metering | Stable drive system, recipe control, viscosity management practices, precise metering adjustments and calibration routines |

A selection checklist you can actually use

If you’re comparing suppliers, this is the fastest way to avoid “apples vs. oranges.” Bring it to your next internal meeting and score options honestly.

Define your coating target

- Substrate: film / paper / foil / textile / specialty

- Coating type: water-based / solvent-based / hot-melt / UV-curable (if applicable)

- Target coating weight range and tolerance

- Line speed targets at stable quality (not “max speed on brochure”)

Confirm machine features that reduce hidden costs

- Repeatable tension control across key zones

- Changeover-friendly design (access, quick-release parts, minimized dead zones)

- Drying/curing capacity matched to your coating chemistry

- Operator interface that supports recipes and consistent restarts

Questions that reveal supplier capability (these save you from expensive surprises):

- What sample data can you provide that matches my substrate and coating type (even if anonymized)?

- What is the expected scrap rate during commissioning, and how do you reduce it week by week?

- How do you validate uniform airflow and temperature distribution in the drying section?

- What are the typical cleaning steps and time for a full changeover?

- How do you support spare parts and troubleshooting across time zones?

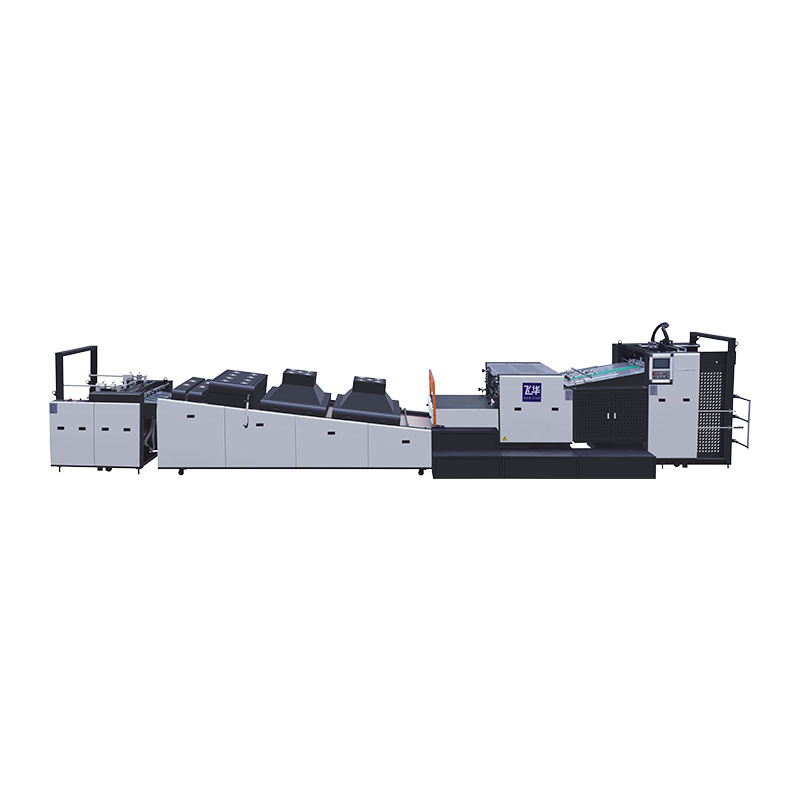

Where experienced builders help: Teams such as Wenzhou Feihua Printing Machinery Co., Ltd. often add value not only in the machine build, but in matching the configuration to your specific materials and throughput goals—especially when you’re scaling from pilot runs to steady production.

Commissioning and ramp-up tips that protect your schedule

Even the right Coating Machine can disappoint if commissioning is rushed. These practical habits reduce early scrap and shorten the learning curve.

- Standardize a “first good roll” routine: Define warm-up time, viscosity stabilization steps, tension setpoints, and a restart sequence after stops.

- Lock down cleanliness basics: Dust control, filtration, and controlled handling reduce random defects that look like “mystery chemistry problems.”

- Train for repeatability, not heroics: Your goal is the same results across shifts, not one operator who can “make it work.” Use recipes and documented adjustments.

- Track three numbers weekly: scrap %, changeover minutes, and customer-return rate. Improvement becomes obvious and defensible.

If you treat ramp-up as a controlled project—with clear acceptance criteria—you’ll protect both output and team morale.

FAQ

Q: What’s the first spec I should confirm before requesting a quotation for a Coating Machine?

A: Your substrate + coating chemistry + required coating weight tolerance. Those three determine the coating method, drying needs, and the stability targets for web handling.

Q: Why do defects often appear right after a stop or splice?

A: Stops change pressure, temperature, and flow behavior. Without repeatable restart steps and stable tension zones, air can get trapped and coating weight can swing until the system stabilizes again.

Q: How do I know if drying capacity is the bottleneck?

A: If the coating looks fine at lower speed but becomes tacky, blocks, smells, or causes lamination issues at higher speed, drying/curing is likely limiting throughput more than coating application is.

Q: We run multiple products—how can we reduce changeover time?

A: Prioritize quick-access design, simplified fluid paths, and stable recipes. Also standardize cleaning tools and define a documented “clean-to-run” process so changeovers don’t rely on memory.

Q: What should I send a supplier to get a useful proposal instead of a generic one?

A: Substrate specs, coating chemistry notes (water/solvent/solids range), target coating weight tolerance, desired line speed, available workshop constraints (space/power/exhaust), and your top two pain points (e.g., streaks + long changeover).

Ready to turn your coating headaches into a stable, repeatable process?

Tell us your substrate, coating type, and target output, and we’ll help you map the right Coating Machine configuration to your real production constraints. If you want fewer defects, faster changeovers, and a line your whole team can run confidently, contact us and start the conversation.